Interview with Brightwell’s Head of Design

Since Brightwell was founded in 1947, we have always endeavoured to offer innovative quality dispensing solutions. With our in-house product development, production and quality control teams based in Newhaven in the UK, we can take advantage of this flexibility.

Our commitment to innovation, customer focus and product development is key for supplying our customers with product solutions. Our teams work tirelessly behind the scenes to manage and improve our supply chain, and our product design and development department have the capability and flexibility to quickly redesign critical components that would otherwise potentially cause delays for our customers.

We asked Brightwell’s Head of Design, James Burn, how the internal resources available at Brightwell Dispensers assist with this process.

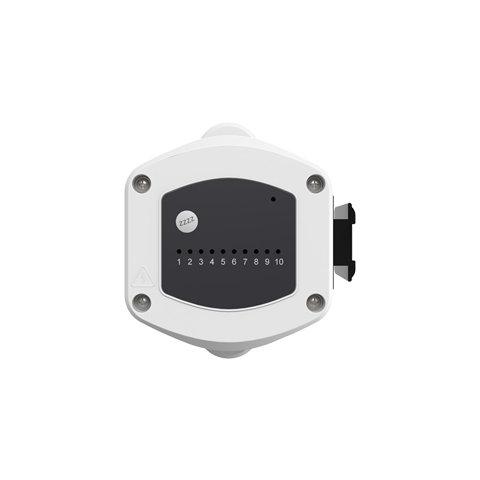

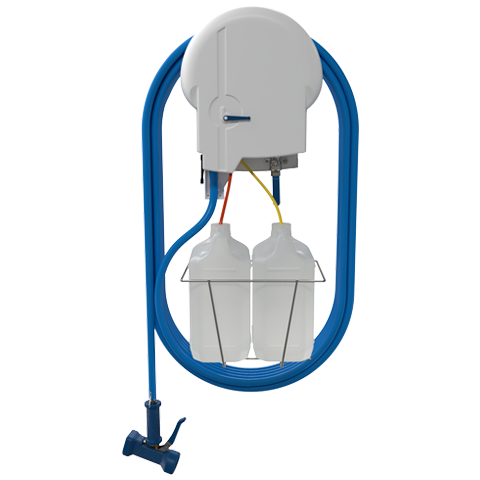

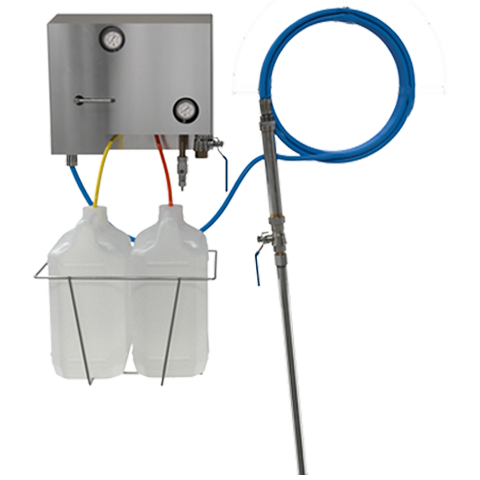

James, you have recently had to redevelop the microcontroller and other extended lead time semiconductors due to global supply issues – parts critical to the supply of Brightwell Dispensers BrightLogic laundry dosing systems. How did you go about this?

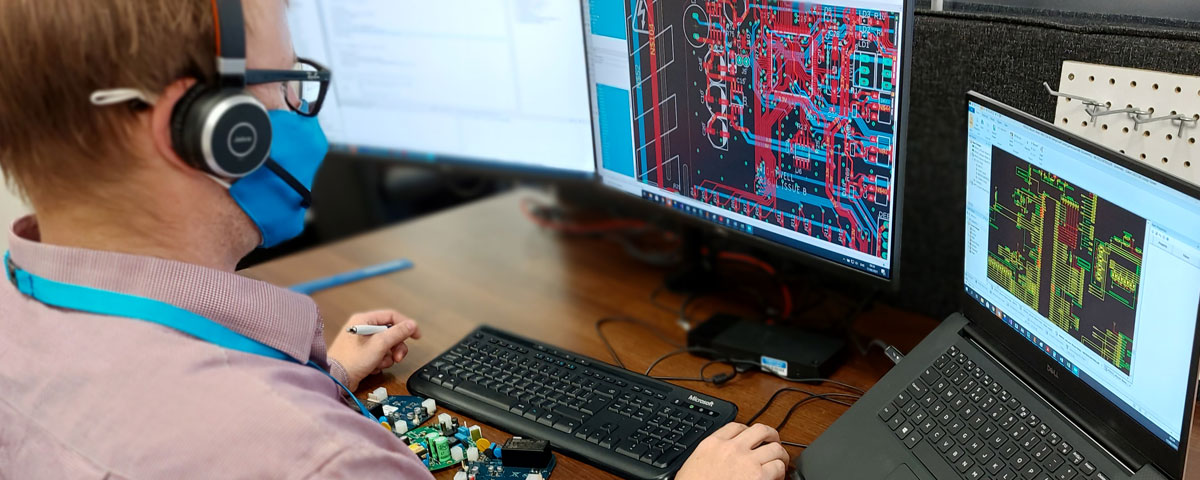

The supply of the microcontroller and some semiconductors, critical to our BrightLogic laundry system, became scarce, and alternatives had to be found and engineered into the products. Working closely with our suppliers and procurement department, we reacted quickly to redevelop the circuit boards along with the associated firmware.

Our key aim was to avoid any disruption to our customers. Components were identified based on ongoing availability, and their supply was secured, working closely with our procurement teams to ensure continuity of supply. Once the circuit boards were redesigned, we conducted thorough tests to make sure that our systems worked.

What was the turnaround time?

To complete the design work took around two weeks as we have in-house expertise in hardware and software development. Prototypes were manufactured and tested both in-house using our newly installed testing facility and in the field.

What resources did you have to be able to do this?

Brightwell Dispensers is fortunate to have a multi-skilled team of engineers and designers. Working closely with our agile procurement department, we were able to be flexible with our supply chain and adapt to changing supply chain conditions. Co-ordinating with our production department, prototypes and trial builds were planned and completed quickly and efficiently.

Now in our 74th year, Brightwell Dispensers remains an active member of an ever-changing industry, always striving to meet and exceed our customer’s needs.

Please get in touch with us with any questions you might have.